SUM3D AMM: Advanced MultiAxis Machining

SUM3D AMM: Advanced MultiAxis Machining

AMM, Advanced Multiaxis Machining module, empowers SUM3D performance, providing new and multiple working strategies from 3 to 5 axes.

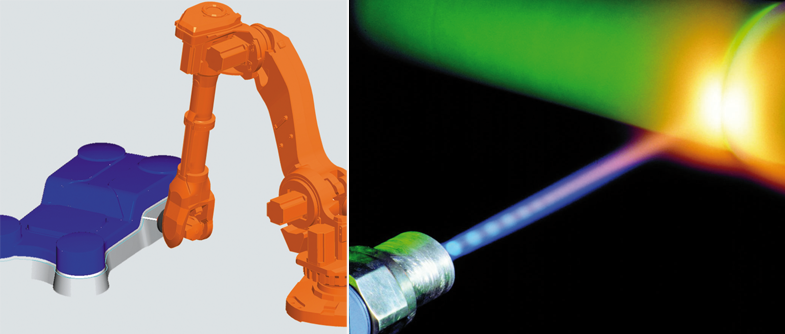

Those potentialities allow effective problem-solving in programming multifunctional or robot 5 axes machines.

The aim is to reduce machining time for the phases of roughing, semifinishing, re-machining and finishing and to obtain a finished piece while avoiding post machining operations of re-positioning or re-finishing by means of other technologies (for example with electrodes).

- Different strategies to set the development of the 4/5 axes toolpath

- Advanced tool axis orientation systems with the possibility to manage the tool contact point and limit the working range. The orientation can also be applied to the SUM3D standard 3-axis machining.

- Four levels for collision checking, of all the movements performed by the tool both in contact with the piece and in repositioning. These checks are performed on the surfaces to be machined and on all additional surfaces specified by the user (eg equipment).

- Complete management of the connections, that is all the movements to be performed in case of interruptions in the path (cracks or parts not to be machined), between the increments of the pass and of the attachment detachment.

- Management of the security area given by layers, cylinders or spheres.

- Management of the blank that determines the cropping of the possible part of the path to empty.

- Management of various roughing strategies also optimized for specific needs (impellers or turbines).

- Conversion of any type of parallel passes in spiral machining.

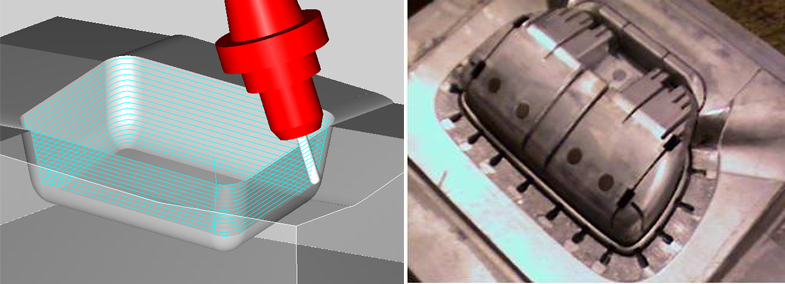

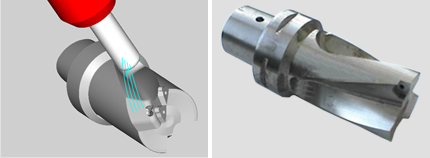

Moulds

In this field the benefits of AMM module are:

- Possibility to work maintaining the flank of the tool always parallel to the shapeless surfaces, in order to obtain better finishing in shorter time (considering that in this case increments could be higher).

- Use of shorter tools and 3 axis machining for all the parts without tool or spindle collision. Only for collision areas the tool will be rotated by the user.

- Machining or re-machining areas with deep cavities avoiding to finish them with the electrodes.

- Machining undercut areas avoiding piece repositioning.

Industry

In this field to reduce machining time is a must. For this reason multifunctional machines are often used in order to produce the whole piece with the minimum number of repositioning and the best quality. AMM fully manages the milling process with this specific features:

- Roughing, re-machining and concentric finishing of any kind of cavities with 4/5 axis.

- Re-machining or finishing of corner or small radii areas, using the side of the tool.

- Particular machining for cams, pipes, impellers, turbines, wormscrews, extruders or tools.

- Toolpath control, by means of real cinematic simulation, to reduce the time spent on the programming optimization.

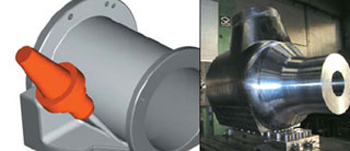

Specific machining for petrochemical, water and gas industry

Companies producing forgings or valves, pipes and flanges will benefit from using AMM and SUM3D, thanks to the specific machining optimized to obtain roughing and radial finishing by managing the rotating table.

In this way the working time is dramatically reduced while the quality of the finished product is considerably improved with a consequent decrease in polishing time.

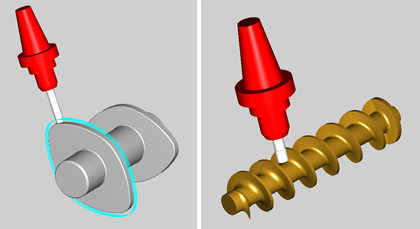

Cutting tools machining

When machining metal cutting tools, it is necessary to mill the flutes in a 4/5 axis simultaneous mode. It is crucial to reduce the machining time because these kind of products are very expensive. This short-time machining can only be achieved with a very smooth toolpath based on Direct-to-Bezier and/or Nurbs-Surface Toolpath Calculation.

The AMM module allows to obtain:

- Roughing and finishing machining with 4/5 axis or continuous positioning.

- Vertical surfaces finishing with flank tool (also in case of conical tools).

- Repeat of all machinings of a propeller to achieve the complete processing of the tool.

- ISO 5 axis drilling or, if possible, CNC’s fixed cycles management.

Exhaust Manifold Machining

One of the most complex tasks in building motors prototypes is milling the exhaust ducts of the cylinders.

With the help of the multiple strategies of machining, AMM provides a consistent reduction of processing time.

It is possible to machine in a perpendicular to a curve and manage the movements of approach, detachment and increase always with a user-defined curve.

Besides, AMM Multi-Step collision control provides all the options needed to combine multiple collision avoidance together with the ability to handle undercut tools like ¾ sphere cutters.

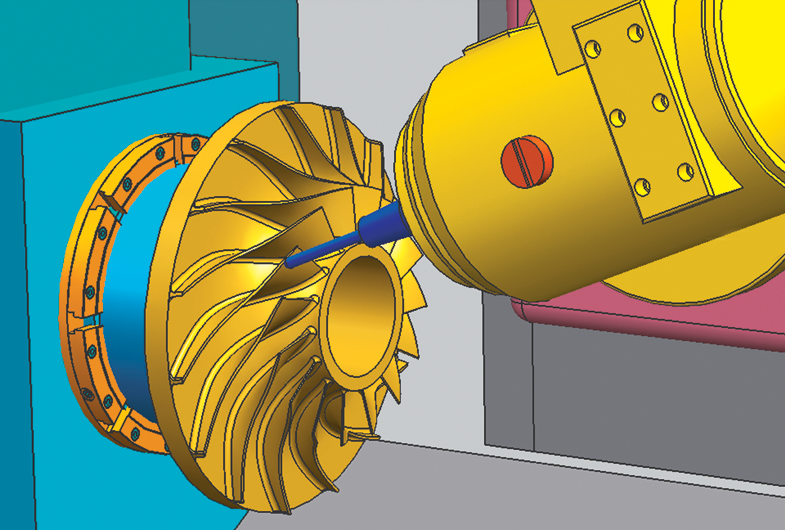

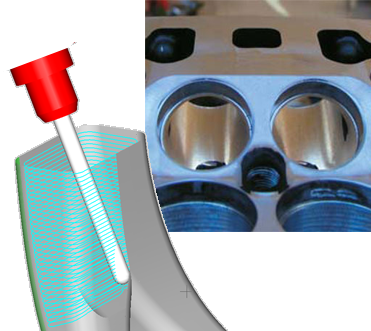

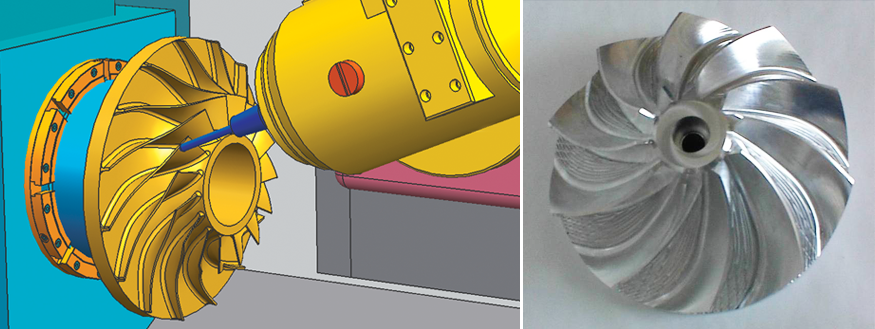

Impeller and turbine machining

Machining of impellers and turbines is one of the most complex kind of milling. Best results in machining of impeller ribs, are achieved using conical tools with deep cut steps based on the stock definition of upper and lower surface.

Another important feature of AMM is the ability to dynamically adjust the federate speed and the maximum distance between programmed points of the axis.

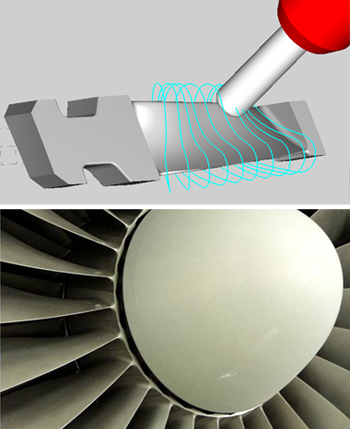

Machining of turbine blades

Turbine blades have always been a test to prove the efficiency of a 5 axes CAM system.

AMM is able to calculate roughing, re-machining, semifinishing and finishing toolpaths with the ability to automatically handle cutting planes and the relative tool’s angle.

This allows a great reduction of the programming time as toolpath changes are realized in a very short time.

Multisurface finishing, with the use of bull nose end mills and thanks to AMM’s ability to detect collisions between the tool and the piece, improve machining time. In this case it is also possible to use a spiral toolpath.

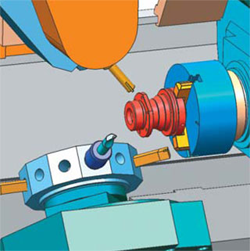

Eccentric machining and mill turning

AMM offers multiple functions for Eccentric Shafts machining. Camshafts and connecting rod can be milled with simultaneous 4 axes with collision check. Other applications are complex particulars like wormscrews for plastic and rubber injection moulding. It’s possible to plan multi-step toolpaths for roughing and finishing avoiding unnecessary tool’s moves also in case of very complex surfaces.

Machining of details for footwear companies

AMM allows undercut parts machining without re-positioning of the piece. For instance, it’s possible to generate a 5 axes spiral toolpath to work the whole heel. Furthermore, in case of machining of matrix with undercut areas, deep cavities or corners, the tool’s dynamic angle can be managed depending on collisions. In this way there’s a 3 axes toolpath without collisions and a 5 axes one where the tool starts to collide.

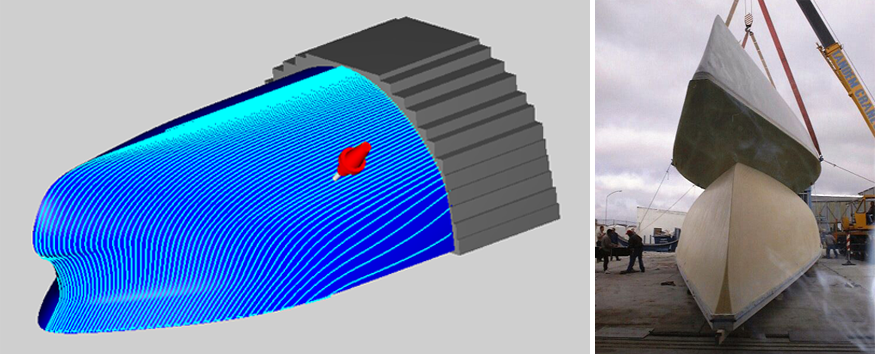

Shipbuilding industry machining

The flexibility in AMM allows to program both removal and deposit machining, used widely in shipbuilding field. Especially in case of machining of keels, the multiple strategies that AMM and SUM3D offer can meet the production requirements.

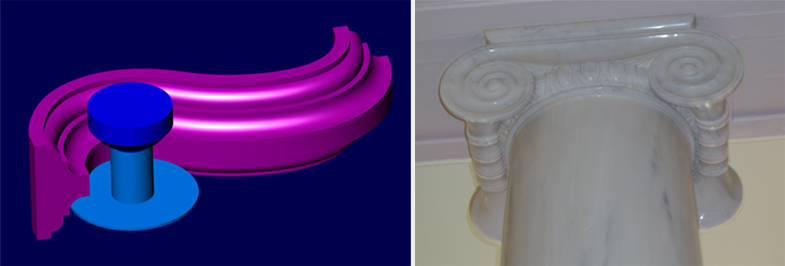

Machining of marble details

Many machining techniques for marble have been included in AMM to work with 5 axes and/or with turning functions’ CNC. The specific features studied for this field are: roughing or finishing using disc mills, machining with shaped tools, polishing and managing the technological part on the basis of the specific tools used in this industry. Furthermore, there are optional modules available for the machining management starting from laser or mechanical digitization of parts to be realised duplicating a sample (logos, plaques, capitals and statues). The mesh surfaces coming from the scan can be machined with 5 axes AMM also with disc tools.

Machining of woodden parts cut

AMM’s functionalities, together with SUM3D’s, allow to realise toolpaths to fit the purposes of the furniture industry and of the companies producing custom parts. To machine standard parts for industrial production it is possible to create repetitive schemes to be applied to the different models. For all those companies producing custom parts, the simple and flexible AMM module allows to perform toolpaths to machine any complex shape.

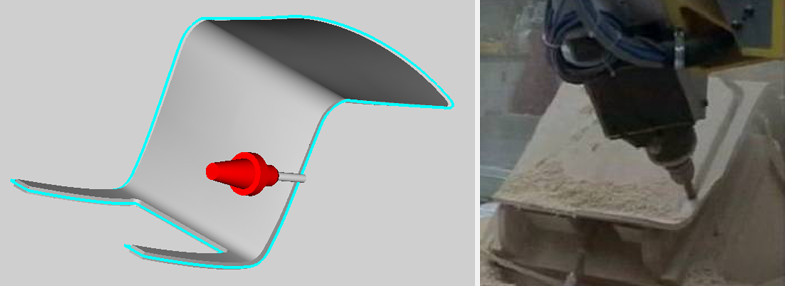

Laser cut machining

AMM can machine curves projected on surfaces in order to produce cuts of parts like metal sheets, plastic or aluminium. Multiple possibilities of orienting the laser head, even through a series of vectors drawn by the user, enable to accurately manage all positions of the axis in each area. This strategy, together with optional solutions for the cell management, allows to program laser robot too.

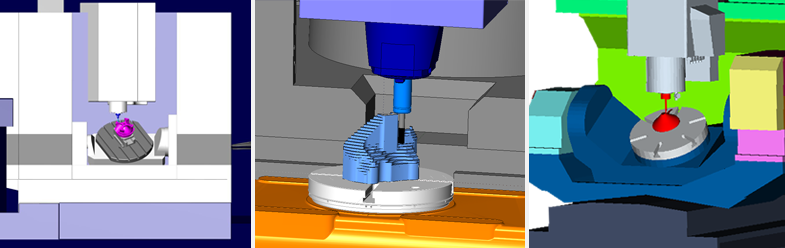

Kinematic Simulation

The kinematic simulation module allows a realistic representation of the whole CNC machine showing the movement of all axis, both linear and revolving.

The aim is to avoid unnecessary attempt on the real machine and to be sure to work the piece without any problem related to limit switch or collisions with the equipment.

Collision check

During the machining all surfaces of the work piece and of the toolholder are in risk of collision.

In this case the AMM module gives many options to avoid these risks using, if necessary, different orientations of the axis. To avoid collision, the surfaces that will not be milled can still be selected for this control.

Multi-axes Postprocessor

Most of 5 axes machines postprocessor are available. Additional postprocessor can be developed in order to satisfy client’s need. Furthermore it is possible to draw and activate the geometric part of any 3 or 5 axes machine, in order to be able to display it on the kinematic simulation.

Overview

Overview Features

Features AMM Module

AMM Module Functionalities

Functionalities Requirements

Requirements Additional Modules

Additional Modules