Stay up to date with the latest features and releases of Make&Mill.

Stay up to date with the latest features and releases of Make&Mill.

2021

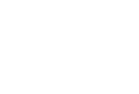

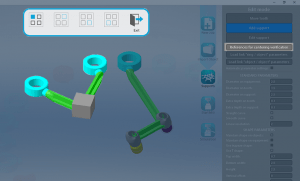

OVERLAY CHECK

Thanks to this new function the software will send you an alert in case of extreme objects proximity. You can now better protect your project from damages and be sure about the final result.

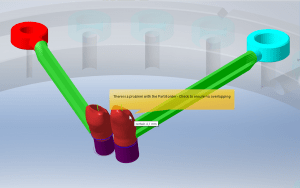

3D PRINTING SOFTWARE INTEGRATION

Make&Mill is now perfectly integrated into our printing software Pyramis. You can execute the entire workflow and switch between the two software interfaces in just one click.

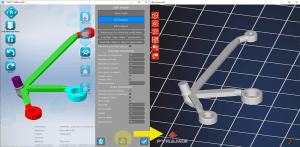

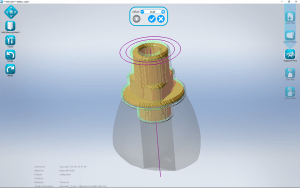

DETECTION OF SECONDARY AXIS

Thanks to this function you now have the opportunity of better refining complex objects while reducing manual operations in case of simple projects. As a benefit you will save time for your operations and reduce the risk of manual errors from operators.

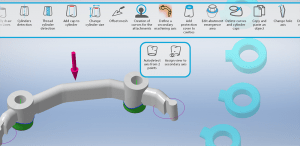

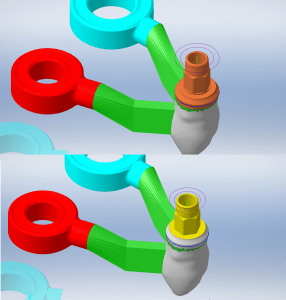

ADD A PROTECTIVE COVER TO AN EXISTING INTERFACE

To optimize tool consumption is now possible to add shaped protective covers with radial offsets to the piece of an interface.

2020

OFFSET MESH

Make&Mill allows you to select only the areas you need to modify by adding material. This can be an essential function in case of calibration errors on printing machines or to refine the object to get a better product at no effort.

REPLACE FUNCTION

Now the replace function in M&M can be executed even if the object is linked to the connectors. You can now you replace what you need whenever you need, regardless the project status. Execute the replace function while keeping the connectors also gives you the certainty of keeping the object in the same position.

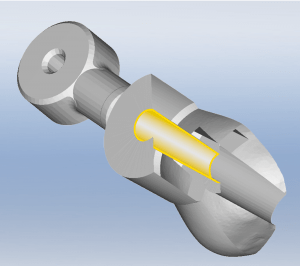

PROTECTIVE CUPS WITH SCREW HOLE

The function of applying protective caps with screw hole gives you the possibility of reducing tool consumption and calculation time. Moreover, thanks to this function enhancement you could also handle even cases where none of the connections have a screw hole.

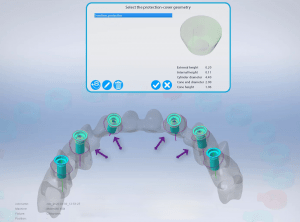

MULTIPLE INTERFACES PROTECTION

Make&Mill is now able to select multiple connections at the same time to apply the same type of protection, this allows you to save time in getting the final result.

News & Releases

News & Releases Brochure

Brochure Overview

Overview Features

Features Requirements

Requirements Integrations

Integrations Video

Video